Header Title

New narratives for lighting manufacture – based on plant polymers

Lamps have long resided in the (disposable) “products” category – with B2B mindsets focused on commercial and practical benefits. Gantri digital manufacturing is rethinking that whole narrative

Lighting systems are pretty much stuck in the doldrums with regard to how they’re described and marketed. The basic narratives about what their manufacturers/designers do, and how they do it, hasn’t changed much over the years, except for various rounds of new “packaging”. There’s usually bucketloads of flowery prose about shape, elegance, exclusivity and lighting effects, while the real messaging focus is almost always on the hardware “product”, with little info on what the lighting system is made of – or how, or where. Or any deeper “why” purpose.

This post is about a US company that has broken the mould for positioning narratives about designing and manufacturing lamps. What’s more, they’ve done so in just about all directions at once – a rare feat. I seldom write posts about individual companies, but this particular setup seems to have adopted noteworthy positions in several dimensions. The more I dug beyond and behind the website window, the more was revealed.

Show not tell

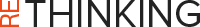

Gantri is a San Francisco-based company that doesn’t define or position itself as a lighting company or manufacturer at all – they claim to be “a passionate group of designers, engineers and makers”. Their website reveals a strong, stand-out visual narrative that doesn’t even show or mention lamps until right at the end. Instead, we’re led through the processes and technologies that bring forth what ultimately ends up as a lamp, and are intrinsic to explaining its shape, surface finishes and capabilities (in all dimensions).

This is a powerfully different “show not tell” approach that makes the impact and coherence of the company’s ideas stand out. When even the production equipment is made to look this good, it’s difficult not to notice the messaging.

Droolworthy Gantri Dancer – custom-engineered four-gantry 3D printer

Yes, there are other companies in both the lamp design and plant polymer spaces that also feature evocative, image-heavy landing pages. But the strength and depth of such sites usually peter out the deeper you go. Generalising horribly, most such companies build on one core idea as the selling point, with the “how” left pretty invisible. Sales trump transparency.

Designers need to stop making pointless stuff that looks nice

Purpose-driven narrative precedes product

Most manufacturing setups have a natural engineering/design tendency to highlight “what” they do – their products and services, etc. – and only then (though rarely) explain the “how” and “why”. This is particularly true for lighting systems, whether for commercial or consumer markets. German-based ERCO is just one obvious example.

Perhaps because this operation doesn’t stem from a traditional mechanical lighting manufacture background, California-based Gantri seems to have taken a distinctively different approach. Beneath the apparent simplicity and tasteful white-space design, the company’s website is surprisingly multi-dimensional and comprehensive – there are a lot of powerful statements and strategic messaging positions in there, although it’s kinda’ like peeling an onion to make reveal these gems themselves.

The overall point is that – unlike many “purpose-driven” companies – the core-purpose “why” at Gantri doesn’t seem like an “add-on” at a different conceptual/strategic level than practical manufacturing operations. Instead, it is communicated as integral to the entire mindset, business model and commercial structure, with the interaction between theory and practice clearly on display.

Materials mojo

Plant-based plastics based on polylactic acid (PLA) are well-known for having certain specific downsides. Most Gantri lighting products are therefore made of a new, proprietary type of plant-based polymers co-developed by Gantri and the Netherlands-based materials company colorFabb. According to Gantri itself, these polymers – sourced from sustainably-farmed sugar crops that include corn and sugar beets – are the world’s first plant-derived polylactic acid (PLA) blends that are specifically formulated to overcome the well-known downsides of PLA blends. To achieve high-quality lighting products, significantly higher temperature resistance along with effective light diffusion are essential. For all parts exposed to higher temperatures, an opaque, temperature-resistant blend finished with a water-based paint is used. For the parts through which light has to pass, the company uses a translucent blend that provides a frosted glass-like effect when the lamp is turned on.

One of the strengths of the Gantri narrative lies in avoiding the traditional “technical silos”. Instead, they get right out there and explain how materials and production processes interact and provide practical benefits, providing much-needed transparency at this level, too. Unlike traditional fossil fuel-based polymers often used in lighting systems, such as ABS and polycarbonate, production of these innovative materials only involves the emitting a minimum of greenhouse gases, and they can be easily recycled and reused. And the Gantri difference doesn’t stop with the raw materials and their responsible sourcing.

Manufacturing processes reconfigured

Much modern manufacturing is caught on the horns of an “existential” dilemma. Conventional industrial manufacturing configurations lead to excessive environmental impacts, oversupply and waste, while at the other extreme traditional hand-crafting makes high-quality products too costly, and cannot meet consumer demand.

Gantri addresses this by asserting that the future of manufacturing is digital. The company has built a state-of-the-art factory based around patent-pending Gantri Dancer extrusion 3D printing technology – using fused deposition modelling – to produce quality products at reasonable cost, while doing away with the traditional industrial inefficiencies. The company reckons itself to be the world’s first design manufacturer to use a digital setup to produce end-use consumer products at scale. They call it Gantri Factory.

The combination of plant-sourced raw materials and digital manufacturing paves the way to the sustainable local manufacturing model Gantri insists upon. This approach enables the company to produce high-quality products even in places where labour costs are relatively high – which in Gantri’s case means California. This kind of local manufacturing drastically cuts down on the otherwise huge environmental impact of manufacturer-to-market logistics, as well as enabling Gantri to be wholly transparent about labour conditions and “people care”.

Gantri Factory also features an intelligent production management system that automatically plans jobs for each individual Gantri Dancer 3D printing unit, and adjusts stock levels in real time, thus minimising inventory and storage. The design-for-manufacture digital manufacturing setup also means that the company’s lamps are made only on demand. This maximises output per cost unit, reducing inefficiencies as well as helping to prevent over-production, which is often a big contributor to landfill waste.

In the world of end-to-end corporate responsibility, even sustainable, close-to-origin manufacturing is not enough. The fact that Gantri “owns” the entire digitally integrated process – from materials engineering to manufacturing – also means the company is able to constantly tweak and improve key details, accumulating valuable data in the process. This helps ensure long-term customer/user satisfaction and therefore longer lives for the products – which in turn adds up to less landfill dumping.

Design activity reconsidered

In line with the best of modern thinking, Gantri products are based on collaboration and co-creation.

Visiting the company’s products page reveals that they use many different designers – as do many other lighting companies, of course. However, it turns out that Gantri goes way beyond this to provide a comprehensively featured, structured marketplace for designers around the world (whether studios such as Ammunition, established independents or young newbies). This means individual designers get due credit and recognition, each with his/her/their own profile and “products page” on Gantri. This framework helps these designers build and strengthen their personal “designer” brand as well as relatively painlessly earning income by selling directly to consumers – with the burdensome logistics and admin taken care of. The company operates a revenue-sharing model based on actual product sales to cover the cost of these key services.

On a practical level, there are apparently four essential components in every Gantri light – a dimmable LED bulb, a bulb holder, a metal bottom plate, and a power cable. This paves the way to technical standardisation and quality assurance as well as economies of scale. Crucially, it also means designers can concentrate on what they are best at, without having to spend time, effort and money spec’ing and sourcing the electrical and mechanical “bits” that most people never see, but which have to work reliably and in compliance with safety codes. As explained here, Gantri provides advice about making best use of the designer starter kits, with guidance and instructions about what to consider when designing around them.

The Gantri framework also puts an inclusive, human face on lighting design. For example, a young designer like the enthusiastically eloquent (hardly any “umm”s!) Sam Gwilt has made a series of YouTube videos describing the details and considerations involved in his particular iterative design process. Revealing and highlighting these convoluted creative processes draws in potential customers, and makes us much more willing to spend our hard-earned dosh – because we can see and appreciate the conceptual sweat and hundreds of rejected mis-steps and developmental dead-ends we’re actually paying for.

Become a Gantri designer to create designs and sell them online. All for free

Sales models integrated

At root, most lighting companies simply “sell stuff”, and unless there are direct B2C sales channels, the sales machine is usually tucked away. There’s a jungle of wholesalers, price agreements, agents, niche concerns and exclusivity issues out there, all rooted in conventional business-as-usual expectations and comfort zones.

Gantri seems to be taking a slightly different approach – at least in part. The website features an “inspire and earn” affiliate marketing setup – apparently using ShareASale – that enables people to earn commission by featuring Gantri products in original content (whenever it leads to purchases). This helps establish a growing referral/influencer community for the Gantri mindset and its products (in addition to the Gantri designer community). Crucially, it also makes it quick and easy for such people to post content on all social media platforms, thus building the buzz still further and more effectively.

But there is also a conventional online shop – attractively presented and apparently idiot-proof, to maintain the quality of Gantri customer interaction and communication.

Platform for opportunity

As Gantri points out (I’m paraphrasing a bit, but they say it here) traditional manufacturing setups stymie human creativity by making it difficult as well as costly for designers to bring groundbreaking ideas to market. To help rectify this, Gantri has moved way beyond mere box moving and product shifting.

This company has re-considered and re-thought the way lighting is developed, manufactured and sold, empowering creatives of all kinds (from anywhere) to create design-forward, functional pieces, and supporting their creative visions with high quality and unmatched attention to detail during production. The company’s manufacturing technologies are also more efficient (they say) and more environmentally responsible – making designers’ work significantly more attainable and sustainable.

Gantri’s mission is to empower design

Gantri morphs seamlessly from a company/product showcase into a platform for selling designs – the phrases “on Gantri” and “designed on Gantri” begin to flourish. When the processes and structures are considered without referring to the physical product – lamps, in this particular case – the big perspectives begin to kick in, revealing a well-considered – and seemingly effective – platform for transforming thoughtful design into attractive, affordable products, via a responsible, inclusive business model.

Taking responsibility

Gantri seems to be a company that has “taken ownership” of what it’s doing, and put it in a much wider and more responsible context, being explicitly transparent about every aspect of operations – from idea to disposal. The result is a comprehensive narrative that seems very convincing.

This unique approach allows us to bring beautiful, one-of-a-kind designs to you in a way that directly supports each designer while being kinder to our environment

In the same way that Tesla isn’t really a car manufacturer, this isn’t a narrative about designing and manufacturing lighting systems. The Gantri model seems to add up to a breakthrough way to develop, manufacture and sell new modern design – in this specific business model iteration it happens to be lighting.

Gantri is selling an idea in multiple dimensions, with the connective tissue of the business model made clearly visible, and making all the component capabilities stronger, more attractive and more meaningful. Way to go, guys and gals …