Header Title

Rethinking simple ceilings – stretchily

Stretch ceilings can be either a low-level practical advantage or a high-level conceptual opportunity – an opening for rethinking architectural design.

Humans (and other creatures) have been building dwellings for millennia – how can it still be possible to completely rethink one of the six enclosing surfaces?

I’ve been (amateurishly) involved with designing houses and repairing ceilings for a long time – either my own, or when endlessly trawling the Internet for good architectural ideas. A recent “discovery” started me thinking about ceilings again – business-wise.

The least exciting surface

In almost any room or public space, the ceiling is usually the least exciting, least decorated and least seen surface. In many modern building structures, the growing need for service, maintenance, repair and updates of all the many fixtures and fittings tucked away up under the near-ubiquitous suspended ceilings, often means the actual ceiling surface is little more than a necessary evil – and an obvious candidate for cost savings if at all possible.

In some buildings, the ceiling is even kinda’ deleted. To save money or to evoke some kind of currently fashionable “industrial chic”, many of the fixtures, fittings and hardware are simply hung from the structure above and left visible. Practicality wins. Grime and dust-collection lose.

Stretching the point

However, I recently chanced upon UK-based Stretch Ceilings – a ceiling solutions company that seems to provide a refreshingly different take on ceilings, and whose products raise some interesting questions and perspectives.

Yes, these, too, are suspended ceilings. But instead of heavy panels that seem to always need complex, heavy and costly frameworks from which to hang, or to which they can be affixed, a Stretch Ceilings solution simply consists of a perimeter track (made of plastic or sometimes aluminium, apparently) and a lightweight membrane stretched out and clipped into the track. This makes it possible to cover large areas of ceiling fairly quickly, with big savings on all the manpower, equipment and processes required to put up a ceiling, and only a minimum of materials wasted in the process. The company claims almost all types of apertures can be incorporated, including light fixtures, grilles and different kinds of fixing points.

The Stretch Ceilings name also seems to give the company a distinct competitive advantage. Just like Xerox, Kleenex and Hoover, the company’s name is how laypeople would describe the entire product category. It’s great for a company to attach its name to a whole conceptual endeavour or a particular trade/market segment.

Reframing lighting

The Stretch Ceilings approach also seems to provide another realm of opportunity beyond mere ceilings. The world of lighting is normally limited to the actual light source and the tracks, mounts and fittings needed to get electricity into some kind of light-emitting technical fixture.

However, high-quality, energy-efficient lighting is relatively expensive – and only gets more so when more electronics, sensors and adjustability are included in the specifications of any building or structure. Such lighting often has to be somehow embedded in, fixed to or hung from the ceiling of any given space – and this adds considerably to costs.

However, the larger opportunity probably lies in using the ceiling itself as a light fixture. The PVC fabric that the Stretch Ceilings company uses is (apparently) available in thicknesses as little as 0.2mm, thus providing light transmission effects of approx. 75%. This means the entire ceiling surface can be transformed into a massive lightbox – an uninterrupted, illuminated, translucent surface that can transform an entire area.

Furthermore, if the lighting units can be hidden above the ceiling and shine through it, they don’t need to be made of high-spec materials because the actual lighting fixtures don’t get seen – only their effects. This would pave the way to considerable savings in the lighting systems item in any project specification. There would also be dramatic reductions in the time, manpower and other costs associated with jiggling, integrating and juxtaposing the conflicting agendas and practical requirements of two very different trades (ceiling manufacturers/fitters and lighting manufacturers/fitters and electricians). This means internally/backlit ceiling spaces could pave the way to new cost benchmarks for ceiling construction as well as lighting systems.

Dangers from “cowboys” and commoditisation

However, there seems to be an unfortunate sub-text throughout the Stretch Ceilings website – one that speaks volumes of concern about the basic idea being copied and implemented by others less careful, skilled or quality-conscious. This would then leave the whole idea of stretched ceilings (= the company’s name) with a bad rap – in a branch where reputation and perceived quality/capabilities are everything. Stretch Ceilings uses wordings like “directly employed” to gloss over what’s being referred to, but the between-the-lines message seems clear. Knowing the UK building trade from the inside, as I do, this is probably a justifiable concern.

There also seems to be a deeper problem for its business model, in that the company seems to really only sell hardware and materials, and the installation of them. Unfortunately, hardware and materials are both (fairly) easily replicable, and experience in many different industries shows that if current global manufacturing models continue such components are increasingly likely to be commoditised, and to be affected by a downward price spiral. This leaves any hardware-based business model inherently vulnerable.

Part of the problem?

Another issue that the Stretch Ceilings commercial setup will almost certainly have to face lies in the use of PVC as the main visible surface. Polyvinyl chloride is the world’s third-most widely produced thermoplastic polymer. Its most important characteristics include its relatively low price, its toughness and its tensile strength.

Unfortunately, PVC is made from planet-toxic fossil fuels and often also contains a wide range of environmentally hazardous additives. This makes PVC part of the gnarly fossil-fuel legacy and the environmental problems we’re all facing – and leaves the company’s business model inherently vulnerable and possibly open to future wipeout.

That’s presumably why the company has launched a non-PVC option, enabling specifiers to replace the PVC with a polyester fabric with a special polyurethane coating. It would seem a good idea to extend this first step with future-compatible bioplastics or other materials that have positively beneficial effects on air quality – perhaps even actively cleaning, de-activating contaminants or removing electrical charges. It’d probably be better to have a product concept that’s “part of the solution” rather than being immediately seen as “part of the problem”.

Curvy architectural opportunity

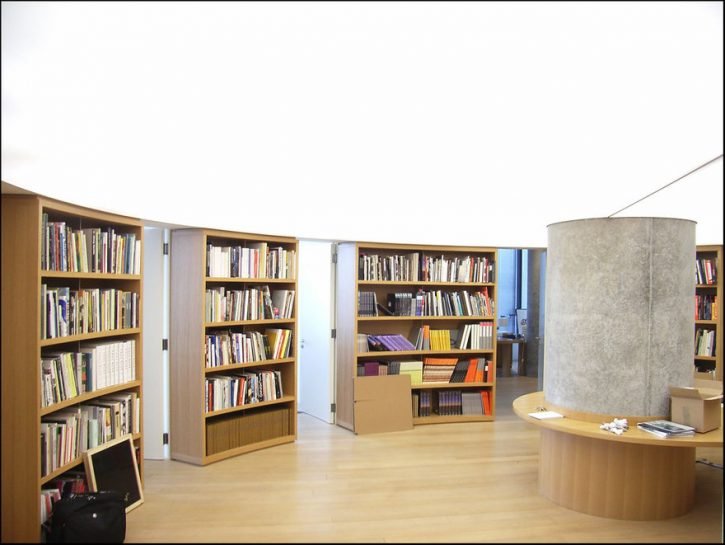

As with many companies in this and similar “hardware” fields, it’s only natural for an outfit like Stretch Ceilings to present the done-and-dusted final results as demonstrations of capabilities and proof of success – see here – and themselves as the supplier. “Case stories” are an achingly familiar, traditional marketing path.

But there also seem to be good opportunities in moving beyond a business model that mostly seems to be about selling plastic and aluminium mounting hardware and materials – though the company does also extend its reach by selling systems that incorporate lighting and graphics (where profit margins are presumably better …).

There also seem to be a much more valuable market-positioning potential. Stretch Ceilings (a metaphor, for all other companies doing similar work, of course) can provide a way for architects and designers to rethink the contexts and capabilities of shapes, curves and surfaces. The post-Zaha Hadid generation of architectural design and mega-conceptualisation and Chinese statement structures is no longer wed to straight lines. Architecture’s “Queen of the Curve” transformed the contours of modern design, and computer-generated shapes have now made it possible to transcend and abolish the angularity and straight lines once a central feature of all building work

Capabilities like those from Stretch Ceilings (etc.) can help provide cost-effective ways to create curved profiles or to form three-dimensional shapes, domes and vaults that are much in demand but difficult to build using conventional straight-line techniques and materials. And thus provide a path to creative exuberance and breakthrough design, as well as winning tenders. These technical capabilities (based on difficult-to-replicate specialist know-how and problem-solving experience, rather than mere hardware) can then be positioned and marketed as a commercial success generator for dozens of clients – architects, interior designers, structural engineers, etc. – in a one-to-many business model selling know-how and capabilities.