Header Title

Digital twinning and new perspectives for “technical sales”

Selling technical equipment has long been plagued by “what if” uncertainties. But what if customers could see how new equipment would help them?

Struggle for mindspace

I’ve been working with B2B companies involved in what can be loosely categorised as “technical sales” for decades.

One of the biggest hindrances to such sales efforts is the need to be “top of mind” at exactly the right time – when the actual sales opportunity arises at some unknown, unpredictable point in the long, complex cycle of equipment obsolescence, service life expiry, planned replacements and unforeseen/unforeseeable events that together demarcate the playing field for the purchasing decision. A lot of time, money, marketing material and manpower gets spent on this striving after being “in touch” at the point when this mythical, unpredictable event happens, and the “lead” turns into a much-vaunted “sales opportunity” that justifies all the time-consuming groundwork.

There’s an entire industry of trade fairs, sales rep visits, professional networking, travelling exhibitions and suchlike applied in pursuit of this amorphous mindspace real estate – and these all add to costs and siphon off the time and energy of a company’s limited expert manpower.

Two realities

One could also say it’s fairly bewildering how much “technical sales” effort is expended on trying to match two very different realities – or even getting them close to speaking the same language.

On the one hand, there’s the potential customer’s multifaceted framework of practical requirements, technical expectations and operating ambitions, as well as all the quagmires of organisational, commercial and technical uncertainty that can make or break careers as well as bashing profit predictions out of shape.

On the other hand, there’s the salesforce’s natural, inbred focus on tech specs and claims/postulates about what the equipment or product should be able to do, or should help the customer achieve. Most of such claims are unproven for each particular customer – in whose squishy, unpredictable, irrational heads the actual uncertainty is embedded.

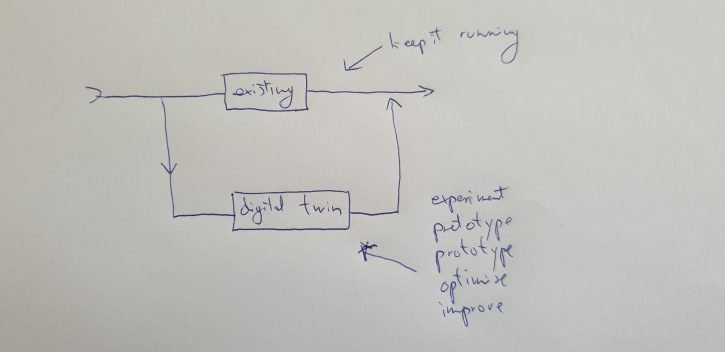

This all means there are two divergent realities at play – the former focused on the whole and keeping it running smoothly and productively – and painfully aware about the proverbial chain only being as strong as its weakest link. The latter – quite naturally – has a very different focus, built around the specs and details of the product/equipment being pitched to meet the need, whose real, human-embedded contours are often disconcertingly vague and fluid.

Nobody wants disturbances

In most big-money “technical sales”, greenfield/blank slate setups happen only rarely. Such events are usually the outlier instances – the exceptions that prove the rule. In practice, most kinds of “technical sales” involve attempts to insert new products, equipment or systems within complex frameworks of existing systems and hardware that are already working. As a result, this usually involves navigating minefields of vested interests – commercial, personal and career-based – as well as dealing with a considerable natural fear of disruption and disturbance – “if it ain’t broke, don’t try to fix it”.

However, the digital dimension is increasingly becoming the lingua franca of engineering, manufacturing and processing operations in all their myriad forms. The digital transition opens significant new opportunities for “technical sales”.

Sprechen sie digital? Painless insertion

Digital design and engineering are increasingly common in virtually all branches of engineering and technical processes, as part of integrated modelling, CFD dynamics analysis, etc. As soon as equipment is scanned into (or built with) digital tools such as SolidWorks, the 3DEXPERIENCE® platform and CATIA Mechanical Designer from Dassault Systèmes or the Onshape software-as-a-service (SaaS) product development platform (all of which I’ve written about elsewhere), it has a digital identity or representation that can make it a candidate for digital twinning.

Digital twinning – risk reduction

Digital twins are virtual counterpart representations of real-world physical objects, structures, equipment or processes. Existing alongside their real-world siblings, digital twins can be used to monitor and compare what is happening in the real version, and as a testbed to explore the possible impact of proposed improvements, new components or configuration changes.

The more comprehensive a digital representation of the customer’s operating context is, the easier it becomes to insert digital representations of new products and new configurations to show how – or whether – they would work, without disturbing the customer’s operations and considerably reducing the levels of uncertainty involved. Knock-on consequences and possible glitches become visible, while payoffs and paybacks become calculable.

Digital twinning – and other forms of digital representation, such as augmented reality – enable you to present any new equipment setup or improvements in existing configurations just as they would actually work in situ. This in turn enables a potential customer to “see” what would happen and how it would (probably) actually work. This makes the entire decision-making process much more transparent, as well as removing multiple layers of “drag” based on intangibles such as operator conservatism and managerial preferences/convenience.

And this adds new dimensions to how technical sales can be conducted …