Header Title

Designed comfort evolves auxetically

From Aeron onwards

One of the (many) benefits of being my own boss is that I’ve almost always planted my precious posterior in a Herman Miller Aeron office chair. Designed by Don Chadwick and Bill Stumpf, the Aeron has been pretty much the universally accepted benchmark for cool-cred, ergonomic seating ever since its commercial debut in 1994. The breakthrough thinking behind the Aeron rejected the whole idea of foam and upholstery as the main source of comfort, as well as “democratising” the whole idea of office seating.

I never really considered exactly why my Aeron seemed so comfortable, merely blessing being able to sit, sprawl, fidget and move around on it for 12+ hours a day (one of the less exciting follow-ons from being self-employed!) with absolutely no soreness or strain (except between the ears).

However, I did have a sense of it seeming very indefinably three-dimensional compared with most other/mainstream office chairs. I didn’t think about it much, but I was inside a support structure/machine/mechanical apparatus, rather than sitting on an office chair.

Dimensions of design

Yes, there have been post-Aeron imitators and conceptual knock-offs. Many of them almost certainly cheaper, and probably not as good. Most of them, however, have been fundamentally two-dimensional structures that the user sits on.

I recently encountered two collaborating New Zealand companies that made me think again about this comfort and functionality nexus – noho and its sister company, Formway, part of whose self-description is as a “designer of performance seating”.

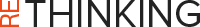

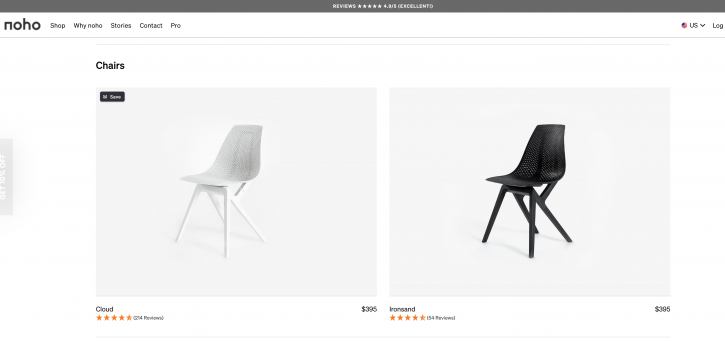

From the noho website

The noho design ethos appears to be well-captured by their comfort by design slogan as well as their Public Benefit Corporation and accredited B Corp status along with a proud boast of being made from up-cycled waste plastic such as reclaimed fishing nets and end-of-use carpets, via the Aquafil ECONYL® process to produce regenerated nylon.

Motion integral to functionality – comfort by design

The company’s “amalgamation of design and engineering, material research and manufacturing processes” seems to represent a new design/engineering approach (performance narrative?) that’s suitable for use anywhere where sitting and posturing are constantly changing. The design of the noho move™ chair seems to reflect multi-functional fluidity – they call it four-way flex – that relates to real-world human activity, body movement and posture, rather than traditional abstract product categorising (chairs for dining, office, hospitality venues, conferences) that stem from legacy retail structures more than forward-thinking user needs.

a chair that moves the way you do

One of the things I noticed was how the noho move™ chair design transitions from traditional “solid” materials to a flexible, responsive shell that works without the levers, struts, springs and dampers of most conventional designs with any similar flexible shape and functionality. I can’t work out from noho website info how it’s actually manufactured (that’s about the only thing they don’t really explain – everything else is clearly and comprehensively accounted for), but it looks as if most of the parts could even be 3D-printed.

What I notice about noho design is the focus on low-carbon footprint waste stream materials engineered into an auxetic-pattern shell in which materials become counter-intuitively thicker when stretched. It seems a bit strange that the noho and Formway websites skip gently and elegantly over the key details of “how” when describing the “Fluid Rocking Motion“. However, there seems to be a balletic elegance in how the material and frame themselves seem to glide, stretch and flex – as when 2D engineering and design morph intelligently into 3D capabilities.