Header Title

Agrivoltaics as a bellwether for “how” rethinks about solar power

New approaches to thinking about agrivoltaic installations – next-generation disruption?

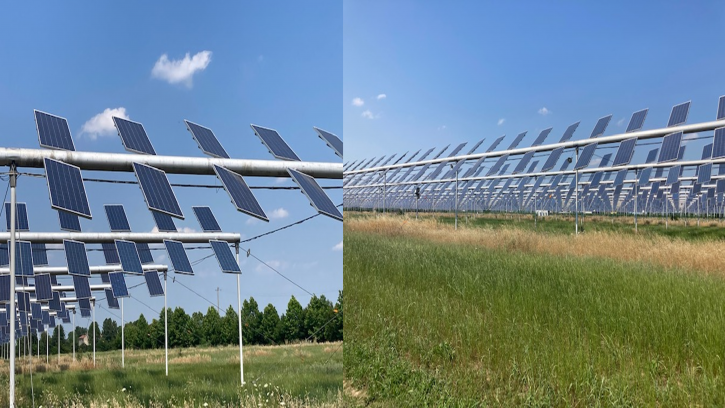

In my professional capacity as a development consultant, one of the client technologies I work with is a small-but-growing specialist corner of the solar energy express train – agrivoltaics. At root, agrivoltaics involve the co-locating of agriculture activities and photovoltaic panels for generating solar energy. Instead of the unfortunate either/or option presented by traditional, land-based solar farms, agrivoltaic solutions provide a “two-in-one” focus on generating much-needed electricity while also maintaining (or even improving) the agricultural, food-producing viability of the land beneath – which can still be farmed with existing machinery and techniques.

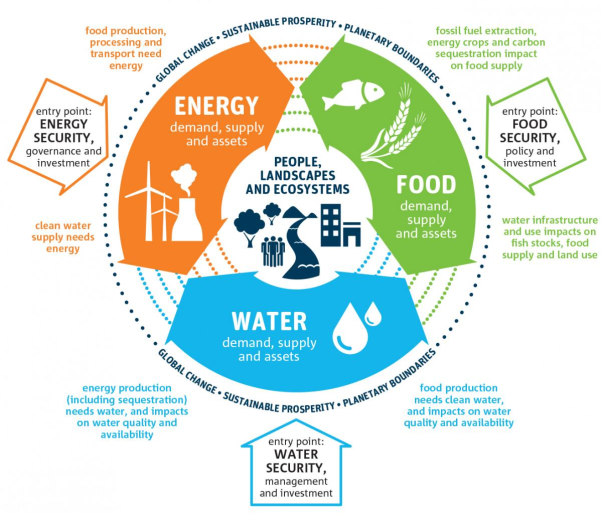

This seems to make obvious sense, because there is only a finite amount of agricultural land available on this planet to feed a constantly growing population, many of whom have growing nutritional expectations. Unfortunately, this limited land area is constantly being encroached upon by other kinds of human activity, and now also by the effects of climate change. It therefore seems contrary to most forms of common sense to plonk energy-generating solar panels on good agricultural land or other carbon-sequestering, biodiversity-enhancing plant growth areas, and thus contribute to screwing up the energy-water-food trifecta still further.

Balance of systems

The more complex understanding of agrivoltaics includes a synergy between the two supporting systems, over and above the co-location.

Agrivoltaics significantly impacts three key factors that affect plant growth and reproduction – air temperatures, direct sunlight and the atmospheric demand for water. The shade provided by the solar panels results in cooler daytime temperatures and warmer nighttime temperatures than with traditional, open-sky cultivation. Using agrivoltaics also results in a lower vapour pressure deficit, meaning more moisture is retained in the air, and less water is needed for crop watering.

Solar panels are inherently sensitive to temperature, so their energy efficiency drops as they (and their surroundings) heat up in the sun. The natural growths or crops cultivated underneath the panels emit water vapour as a result of their natural transpiration processes. This vapour then has a cooling effect on the panels, making them more energy-efficient (per unit of panel area).

Mounting the solar panels in the right way, and – if tracking systems are used – moving them around appropriately makes it possible to shade crops against harsh sunlight, and to protect them against many other weather phenomena that can damage crops or hinder their growth or quality – such as rain, hail and snow. This characteristic feature of agrivoltaics provides agriculture with a whole new realm of control and preventive action (or at least influence) over growing conditions. Such control is particularly important in an era of accelerating, unpredictable climate change.

On the other side of the synergy balance, the solar panels in agrivoltaic systems are mounted either much higher above the ground or in vertically mounted rows, making it possible for all existing kinds of crop cultivation to continue as before. Existing machinery can still be used because it can pass under or between the mono- or bifacial solar panels, which are suspended on wires or mounted on gantries or various kinds of frameworks, either in the ground or 4–5 metres up in the air.

All in all, this adds up to a win-win-win in terms of improving how we grow our food, make use of our precious water resources and produce renewable energy, in accordance with the crucial water–energy–food nexus promulgated by the United Nations’ Food and Agriculture Organization (FAO).

- The benefits include:

- Crop cultivation and (responsible) energy production on the same land

- Preventing crops and getting “baked” by hot sun as well as global warming

- Providing shade for the crops below, and helping create microclimates over which the farmer has more control

- Better growing conditions that make it possible to increase crop yields

- Giving the farmer better control over those growing conditions, with ways to “intervene” when needed

- Less demand for irrigation using precious/limited water resources

- Greater efficiency and productivity in land utilisation

- One important difficulty, however, is that in the real world, the financial returns for any farmer focusing on the energy-producing side of the equation usually far outweigh (by big double-digit multiples) the ROI from agricultural adroitness. This can make full-blown/genuine agrivoltaic solutions a hard sell to hard-nosed investors.

Bellwether for future configurations?

Interestingly, agrivoltaic solutions serve particularly well to highlight several key issues associated with the practical implementation of solar energy, as well as ways of thinking about the “big picture” perspectives involved. Agrivoltaic solutions may seem like an obviously attractive here-and-now approach, but such infrastructure may well have a service life extending over as much as half a century. Shouldn’t we also consider the long-term perspectives? What do we do if market, technology and environmental circumstances change – as they inevitably will? And if they change drastically – as they probably will.

With agrivoltaic solutions, there is a big, natural, agricultural interest in what happens under and around the panels and that takes place in the soil below. In most agrivoltaic installations, the solar panels are inherently multi-functional, and not just “dumb” receptors, nor are they “just” producers of energy.

This all means the overall conceptual scope at the heart of agrivoltaics – as well as the engineering focus – is broader, involving a wider range of narratives and agendas. It helps provide a path forward that lies beyond the traditionally blinkered, silo thinking involved in most forms of energy production – as well as most forms of human activity in general.

Tail wagging the dog

Right from the early days, mainstream solar energy harvesting and solar engineering have been based on some form of solar panels. Solar panels have been the pivotal hardware, the “biggie”, the most visible and the most photogenic element, with serried ranks of panels as the standard visual cliché that defines and conceptualises the whole technology segment. The viability of this technology solution has been pretty much taken for granted, with much of the focus just being on improvements in the efficiency of the aforesaid photovoltaic units. Almost everything else has been considered subsidiary.

With the sublime benefit of a rear-view mirror and in the harsh light of a critical eye, the efficiency levels of these silicon-based panels have been paltry (often well below 20%, in practice). Any improvements have been steady but excruciatingly slow, with gains usually only being marginal. Even the impending transition from silicon to perovskites only involves a relatively small upwards hop in efficiency. When it hits the marketing fan, even relatively small still magically gets presented as very big.

From a wider perspective, however, this overall perception of various types of solar energy harvesting installations can be said to represent “the tail wagging the dog”. Why should it be relatively primitive solar panels, early-generation engineering fixations and historical accidents that together determine current planning and practice for agrivoltaic installations that we’ll probably still be stuck with half a century from now? Why should the ideas behind agrivoltaic solutions be wedded to one singularly inefficient, resource-intensive technology that has a massive behind-the-scenes environmental impact whilst trumpeting and living off its “green” credentials?

The real value of solar harvesting installations – of which agrivoltaics is just a subset – no longer lies in the solar panels themselves. These have effectively just become yet one more FMCG, sourced by the boatload from mass-production specialist suppliers anywhere in the world. One could argue that it’s wildly misleading that such solar panels steal all the conceptual limelight – the resilience, performance and generated value of an agrivoitaic installation accrue from a complex interplay of many different kinds of hardware and software, and many different technologies, including:

- Solar panels that harvest sunlight to produce solar energy

- Solar panels that also provide shade and protection for the crops, soil and microclimate below

- Mounting hardware for the panels and tracking mechanisms

- Sensors that register key inputs and measure the many parameters that tracking and control software reacts to

- Tracking equipment that determines where the solar panels point to achieve required performance goals

- Monitoring systems, control software and proprietary algorithms

- Electrical installations, transformers, etc.

Absorbent, reflective or responsive

Some of the key early “successes” for agrivoltaics were in or above greenhouses, where tailored/managed conditions are essential for different kinds of specialist crops, including flowers and delicate fruits. These were often smaller-scale installations better suited for exploring the relatively new “two-in-one” ideas behind agrivoltaics than larger, open-field installations that normally require a larger financial commitment within a less-controlled environment. Such solutions were less dependent on traditional energy-focused solar panels for top cover, because growing conditions had relatively high priority.

More recent approaches to solar panels include a wide range of solutions in which some or all of the sunlight – and sometimes only certain, carefully selected parts of the spectrum – pass through the panels. This is particularly true using thin-film technologies. If a farmer is able to make real-time, data-driven decisions about how much and what kinds of light pass through – and thus the exact mix of energy generation and crop support – it adds a new tool and new interventionist measure to the farmer’s proverbial toolbox. Conventional solar panels whose capabilities are as-manufactured static will tend to fall behind compared with installations designed from scratch to be adaptive and responsive.

Static or adaptive – the time dimension

Consider the engineering quotient behind current agrivoltaic solutions. These mostly seem to be built on traditional manufacturing mindsets, resulting in static “dumb” hardware and fixtures that are only going to become less efficient over time. Is this really acceptable as an investment profile or as a responsible, planet-guardian business model in 2023 and hereafter?

We actually need flexible, adaptable systems that we can (relatively) easily tweak, improve and upgrade over time to make sure they remain fit-for-purpose, to incorporate new technical discoveries and capabilities, and to deal with climatic conditions that look as if they’ll be changing in unpredictable ways and in patterns never seen before.

If the service life of an agrivoltaic setup extends out to perhaps 50 years, how can it be designed and configured to feature adaptive structures and characteristics? This is increasingly becoming a requirement for many other kinds of societal hardware, from vehicles and aircraft to buildings and “smart” infrastructure. Solar energy setups can’t turn a blind eye to such expectations.

From solar energy to sensors and data

Once solar farm installations are linked to the digital world, and their capabilities are exploited and integrated to the full, the most important output from agrivoltaic installations may not be the flow of electrons a.k.a. electricity, but instead the flow of bits and bytes a.k.a. data. The production of solar energy was originally the main priority, but it may well be that this focus slides down the list of operating priorities because data-driven agricultural practices offer growing returns as a result of greater responsiveness, operating flexibility and effective, well-informed management of agricultural asset value.

Small, often-cheap sensors can be used to monitor a vast range of parameters (air temperature, humidity, wind, radiation, etc.) in the microclimate under and around agrivoltaic installations, and provide detailed analyses of crop conditions and responses. For example, special sensors can be used to measure the active radiation available for the photosynthesis essential for crops, making it possible to estimate the growth of the plant and its specific needs. All this paves the way to more effective data-driven agricultural practices, often featuring proactive and preventive intervention rather than traditional after-the-fact reactive measures. This makes it feasible to cultivate crops much more effectively under managed conditions, rather than subject to the known vagaries of weather as well as increasingly unpredictable climate change.

Value in the form of data goes in the other direction, too. Greater volumes of data sourced from more varied conditions and in different locations make it possible to improve the software algorithms that control and determine the overall responsiveness of the solar farm or agrivoltaic installation in relation to external conditions.

For any company that provides agrivoltaic solutions featuring various kinds of tracking technology, much of the value proposition must lie in the software and the proprietary algorithms that control how these move to determine and maximise energy production, and to optimise conditions for the crops and soil below the panels. Knowledge is power, and in the modern world data harvesting and robust algorithms are prime-value real estate. Whereas most hardware can just be bought, copied and outsourced.

A question of standards?

Successful agrivoltaics rely heavily on data that include the position of the sun, light transmission and shade effects, as well as about the microclimate and growing conditions of the crops under the panels. However, when marketed, sold and installed by countless different commercial groupings, mostly using proprietary configurations, control algorithms and software platforms, as well as a plethora of non-compatible national standards – both technical and legislative – such agrivoltaic solutions and the markets they serve can easily end up in considerable technical fragmentation and proprietary imprisonment. This often makes it difficult for owners, operators and farmers to extract maximum value from any available data, as well as making it difficult to undertake the kinds of comparative analysis essential for well-informed planning and greater effectiveness.

The lack of forward-thinking standards in agrivoltaics might easily end up slowing down and limiting innovation. Any narrow, limiting definitions of what agrivoltaics is – probably rooted in compartmentalised thinking from the past – will probably hinder the pace of technological development. Whereas technical standards aimed at compatibility, flexibility, and constant change, etc. will probably have beneficial effects. Here’s what the Institute for Sustainable Energy Policies (ISEP) in Japan says about the need for consistency or agreed standards.

From the renowned “helicopter perspective”, it seems noteworthy (and regrettable) that agrivoltaic standards and policies seem so conventionally rooted in national interests, with very different ideas and initiatives supported and promoted in different countries. This is pretty much repeating what happened with wind energy, with each country and its government trying to get its hands on a job-building, vote-catching share of a growing and potentially lucrative future market. Yet again we seem to be ignoring the simple fact that neither the problems, nor the solutions, nor the impacts associated with world energy needs and world energy supplies match up with national boundaries.

From mining and manufacturing to printing and flexibility

As a 2023 MIT Technology Review pointed out, “Yes, we have enough materials to power the world with renewable energy. We won’t run out of key ingredients for climate action, but mining comes with social and environmental ramifications.” It’s not so much a question of “what” you do – more of “how” you do it.

Solar panels may get good popular-level press and have been a remarkable success for greenwashing and tech-ignorant policymaking because they produce emissions-free electricity. But their overall path to the solar farms where they may be able to provide the much-trumpeted benefits is often only a weakly greenish shade of deep black. Mining and processing the polysilicon for use in solar panels are at root excruciatingly primitive, polluting and “old-school” destructive. As a result, the earlier stages of solar panel manufacturing often give rise to substantial, irreversible environmental damage – which does not by any stretch of the imagination align with the real intentions involved in the much-vaunted, heavily hyped green transition.

No one really wants to rock the boat about this, not least because huge investments of both money and national prestige have been made in single-technology manufacturing chains for the vast numbers of relatively primitive early-generation solar panels. Nowadays, these are mostly made in China – in 2020 China accounted for 77% of global polysilicon production – and then shipped halfway around the world for installation, with huge environmental impacts. There are also widespread qualms about problematic labour practices in the Chinese supply chain, providing a dubious moral basis for “green ambitions”, although they are all-too-often forgotten in the face of commercial expediency. It seems somehow grotesque that the first generations of solar panels managed to reach the status of low-cost consumer junk, with no reclamation or recycling setups worth speaking of, whilst the technology was still gruesomely inefficient and some of the labour practices behind this galloping commercial success reeked of exploitation and repression.

Yes, this mining and manufacturing can be improved, but in the real world of geopolitics little is likely to happen before huge national investments in single-technology setups based on mined silicon have been paid off. Even then, colossal cleanups will be required to patch or repair the environmental damage done – and such measures are never going to be easy to orchestrate, to finance or to implement.

Investing further in this business model for manufacturing solar power generator units in their early-generation solar panel format is kind of like investing in new manufacturing lines for ICE vehicles at a time when electrification is (probably) about to wipe out the basis for their existence.

Vulnerability and supply chain resilience

In the production of solar panels, as with so much else, the relentless pursuit of economies of scale has recently been called into question by recognition of the geopolitical vulnerabilities that can result from this. There have been notable recent developments in European and other non-Chinese sourcing of next-generation solar panels, but this seems to be more about countering supply chain vulnerability than about ESG profiles for the actual manufacturing processes.

For example, it normally used to take about a month to ship a container from China to Europe or the US. However, such delivery schedules were completely wiped out during the COVID-19 pandemic, and any form of commercial predictability withered on the vine. At the same time, the cost of sending a 40-foot container from Asia to the US sky-rocketed from USD 1,326 in August 2019 to more than USD 18,000 in August 2021.

Concerns about how vulnerable this leaves any energy project that relies on solar panels get kicked into overdrive because other COVID-19 repercussions made (and are still making) it increasingly difficult to source key components and materials from China. If a solar farm or agrivoltaic installation is going to have a service life of 30–50 years or so, and sourcing its raison d’être is so precarious, I think I’d be worried – whether as owner, operator or investor. And I’d want to have at least some idea of where solar panel technology (or other current generators) is likely to go.

Some pundits and researchers predict (see here, for example) that lightweight, high(er)-performance perovskite solar modules will become competitive with modules based on monocrystalline and polycrystalline silicon before too long, because such products will seemingly soon be able to achieve significantly lower manufacturing and balance-of-system costs.

If big, bulky solar panels have become – as a result of all kinds of historical accidents and decision-making snafus over the years – the deciding form factor and engineering framework for photovoltaic solutions, the search is always on for new combinations of materials, layering and processes that pave the way to electrical energy at the lowest cost per watt, at the lowest possible weight, and with maximum physical and electrical adaptability.

There is a constant stream of new discoveries, with photovoltaic-thermoelectric technology as one of the more recent within public purview, and the layered use of ferroelectric crystals in lattice formats teasing energy-efficiency increases by a factor of 1,000. Vast R&D empires have been and huge investments have been sunk into countless combinations of materials layering, substrates, solar cell structures, etc. For the layman, it’s difficult to keep up with all these supposedly “exciting new breakthroughs” – most of which never get beyond the lab or a life in research papers. However, simply replacing various “base materials” with other, marginally more efficient energy producers and innovative material combinations that can bump up electrical efficiency ratings does not do anything to change the vulnerable business model at the core of current solar energy solutions.

Moving on from mining? Thin, printed and organic

Despite these reservations, solar power has come a long way from the original big arrays plonked down on land that can’t really be used for much else. Advances in nano-materials and microtechnology are now paving the way to new kinds of solutions, featuring important benefits that include movability, flexibility and configurability.

One interesting approach to this comes from UK company Power Roll, which promotes a much broader perspective on manufacturing solar panels, as they explain here:

We make two-terminal electrical power generating devices, including solar panels, and at the moment just happen to use perovskites

Power Roll technology is based on three-dimensional microgrooves that channel and direct a flow of energy in thin-film materials of many different types. The company claims not to be “married” to any particular substrate technology or set of materials that happens to be “hot” right now, thus avoiding the constant burden of hardware outdating. For example, the company states that its patented microgroove architecture can be used with perovskites to make solar films that have a carbon footprint only about 5% of that of silicon, and in January 2023 was making public noises about a gigafactory for perovskite solar films, to be located in the UK.

Another – perhaps even more disruptive – approach comes from the world of organic electronics. An organic photovoltaic (OPV) cell is a type of solar cell in which the light-absorbing layer is based on organic semiconductors (OSC) – usually either polymers or small molecules. OPV solar cells are widely considered the third generation of technology for harvesting solar energy.

One company prominently involved with organic photovoltaic solar cells is Organic Electronics Technologies in Greece. This company is also involved in the high-profile Flex2Energy international collaboration project for an automated manufacturing line for integrated printed organic photovoltaics, touted as being the world’s first sustainable production setup for this type of solution.

A slightly different point of origin comes from infinityPV, a Danish company with its core focus on printed electronics and processing equipment for organic and flexible thin films. infinityPV products apparently include an infinitely printed flexible organic solar cell foil that can be marketed as the Energy Tape concept. This would significantly expand the opportunities for lightweight, portable solar power via a reusable energy-generating strip that works a lot like a simple roll of tape.

When thin-film solar-power generation capabilities can (relatively) simply be printed at scale rather than mined and manufactured as a continuation of the old-school industrial paradigm, this ushers in a whole different approach to manufacturing and materials science, along with different ways of thinking about what’s possible and how to do it.

Such solar-power generation capabilities also alter the entire nature of the value proposition. Instead of solar panels being mounted onto other structures, (with added weight as well as considerable visual disruption) flexible thin-film solutions can become part of the structure – as in building-integrated photovoltaics (BIPV). These are products or systems that generate solar energy, and can be seamlessly integrated into the actual building envelope rather than being mounted on it – often as part of building components such as façades, roofs or windows. Similar products can be integrated into the structure and surfaces of vehicles, such as the Fisker Ocean electric SUV and the recently bankrupted Lightyear One solar-assisted EV in the Netherlands, in which most of the horizontal surfaces are covered in solar panels. Such integration possibilities alter the overall value proposition for solar power-generating products and systems, not least because of the explosion in where and how they can be used.

Utilities or usefulness? A question of perspective

In all the Danish agrivoltaic projects that I am familiar with, the big hindrances lie in connecting any big solar energy installation to the national electricity grid, because of snail-pace decision-making as well as the limitations of legacy infrastructure that was never designed or constructed to accommodate the “green transition”. Governments, national bodies and regional authorities want to take as much credit as possible for the introduction of solar energy, but also want to retain their administrative veto rights and traditional “engineering monopoly”. This almost inevitably smothers innovation and flexibility.

Recent research highlighted in PV Magazine seems to show that raw materials and land availability need not present significant barriers to the spread and acceleration of solar energy within the global energy landscape. And that widely used estimates of the levelised cost of energy (LCOE) using photovoltaic technology have consistently been set too high. When such research reveals the many strange, often-unwarranted and unsubstantiated assumptions and “historical accidents” behind planning decisions for solar energy, we seem to have a good basis for rethinking the “how” for implementing the core ideas and ambitions behind solar farms and agrivoltaic installations.

Traditional engineering mindsets, financing frameworks and utilities thinking have normally combined to promote the “bigger is better – and cheaper” infrastructure mantra. But what if smaller, more fragmented and more flexible solar energy solutions were viable and perhaps even preferable for local and on-site use – perhaps even financed less painfully and from here-and-now operating budgets?

US residential energy specialist Sunnova is just one example of a company seeking “independence” from this problematic legacy utilities infrastructure and the restrictive, backward-looking engineering mindsets it entails. Sunnova promotes its micro-utility business model and Energy Independence™ messaging, aiming to replace the traditional bottleneck/monopoly position of traditional utilities that are based on technologically ancient infrastructure that is not built-for-purpose/designed to deal with the needs of an electrified, zero-carbon economy and compliance with the 2016 Paris Agreement protocols.

It seems that growth in the use of photovoltaic energy does not have to be based on utility-scale installations and centralised energy providers rooted in fossil-fuel decisions. Market volume and commercial viability can just as easily come from smaller-scale, distributed approaches using smart-grid technologies and sourcing energy from responsible, low-impact hardware setups that include BIPV, vertical PV, agrivoltaics and floating PV installations. What if smaller, local installations – perhaps even ad hoc, mobile or temporary – could be more-or-less plugged into existing infrastructure for on-site use, thus doing away with the bottlenecks and restrictions often associated with national-grid infrastructure?

Permanent, mobile or temporary

The traditional approach to energy infrastructure is that it is more-or-less permanent – or at least long-term. Huge expense has a natural correlation with the desire for a long service life so the massive investments involved can be amortised over longer periods. This was fairly natural, understandable and unproblematic when the rate of technical innovation was relatively sedate. Now, however, the pace of (potential) innovation has changed dramatically, and legacy infrastructure and systems are often a key part of the many problems for our planet’s future.

Earlier generations of agrivoltaics seem to fall into this category and the traditional engineering mindset from which it originates. But do these capabilities have to be fixed, static and semi-permanent?

For example, H2arvester in the Netherlands has developed a mobile system designed to move around the farm to make the most of changing conditions and deal with ad hoc agricultural requirements. It can also easily be linked up to hydrogen production and/or a battery energy storage system (BESS). Compared with standard agrivoltaic solutions, the H2arvester has the big advantage of moving over the crops, as and when needed. Obviously, it cannot produce as much money-earning energy as any kind of static big-panel setup, if that is the prime parameter. But it releases the farmer from the many financial and practical constraints of fixed infrastructure, and is much easier to phase in and out as technology evolves, capabilities develop and needs change. Solutions like the H2arvester also gel well with automated farming practices, robotics and new kinds of rapid-response agility in agricultural practices.

H2arvester on Dutch television, 16 April 2022 from npk design on Vimeo

There are also other approaches to setting up solar panels in and for agricultural operations. Temporary or mobile setups, for example, can help make it possible to transition from old-school hardware-centric thinking that really stems from utility-scale PV solar plants, over to the use of flexible, standardised modular solutions and business models based on shorter-term financial and hardware commitments.

For example, US-based TenFold Engineering provides a range of self-deploying solar panel installations that can simply be craned off a truck, and that do away with much of the permanence/infrastructure burden. This means a farmer’s investment is not tied down to any specification location or use model – which probably also makes it easier to finance such a solar energy step.

Other location-agnostic, placement-independent solutions I’ve stumbled across include:

Such “bite-sized” hardware seems to provide ideal “get started quicker” development avenues that would enable farmers and other commercial enterprises to get started with various kinds of solar energy setups but without often-difficult/delaying requirements for huge/external investment. These would provide farmers with quickly deployed “tasters” and “proof of concept” setups that could help convince local authorities, planning departments, neighbours, employees and many other interested parties and/or sceptics. In the real world, it’s often better to get started with an imperfect project that’ serves as a minimum viable product (MVP), and to begin harvesting data and gaining practical experience, than to spend bucketloads of time and money planning for the perfect project, the perfect technology and the perfect timing.

Use now – or later

In order to achieve 100% renewables sourcing for use in any electrical grid, something also has to be done to address the fundamental, ongoing imbalance between (on the one hand) variations in the supply of the resource and the output of the technology and (on the other hand) the constant yet unpredictable fluctuations in demand – in terms of when the demand occurs during the day and the amount of energy needed at any given time or place.

Planners are becoming increasingly aware that each particular technology for proving renewable energy cannot be considered in isolation. We also need to address the narrative about how agrivoltaic solutions can best be linked to the utilities net – whether the focus is on consumption or storage, or which mix of these.

This probably means that for effective operation any kind of photovoltaic or agrivoltaic installation will have to be equipped with some kind of battery energy storage systems (BESS) as a buffer between intermittent renewables and variable utility requirements. This key Italian report emphasises the importance of such right-sizing in order to transform variable renewable energy into electricity supplies that can be relied on across the delivery envelope for effectively dispatchable generation.

Big and burdensome or nimble and responsive?

Decisions about energy infrastructure tend to be big as well as costly, and have long-term impacts. Implementing commercial-scale agrivoltaic solutions is a big investment – sometimes up in the “huge” category. Such installations – and solar farms of all types – are usually expected to have service lives extending over decades. In fact, the planned (or hoped-for) length of these service lives has a major influence on the return-on-investment calculations – which are pivotal for whether the project even materialises.

When the points of technical and practical uncertainty are so many, and our climate and weather conditions are changing so unpredictably, the elements of commercial risk associated with large-scale agrivoltaics seem pretty daunting for any farmer or investor. Furthermore, any configuration decision you make will probably lock you into one particular hardware setup for decades to come, leaving you burdened with the “sins of our technical past” for a long time into the future. Somehow this doesn’t gel well with modern realities and the need for flexibility and adaptability to rapidly changing technical platforms as well as new mindsets about global responsibility.

“Ball and chain” or “avenue of opportunity”

Even though agrivoltaics might currently be considered the most exciting solar energy advance since the invention of sliced bread or the wheel, this same agrivoltaics endeavour can easily become just as blinkered as any other specialist engineering focus. There’s not much point in introducing new technology and new thinking à la agrivoltaics if these innovations are encapsulated in old-school perspectives about infrastructure and held back by product cycle timelines that smother any ambitions for nimble, responsive technical solutions to agricultural and energy requirements. Siloed thinking and limited perspectives are almost inevitable … but delays aren’t acceptable if the European Union (for example) is to meet its commitment to a 55% economy-wide reduction in carbon emissions by 2030.

One of the key characteristics of agrivoltaic solutions is that they initially seemed to have escaped the “silo thinking” of traditional solar panel installations that focus (almost entirely) on energy output. It would seem a crying shame if agrivoltaics just become a larger or different silo. We won’t get far by continuing traditional engineering mindsets in which each product/company/technology/country/region just blows its own capability trumpet. The energy and emissions crises facing mankind can’t be tackled effectively by such traditional isolationist approaches.

So this leaves us with one basic question. Do you want your agrivoltaics setup to be a “ball and chain” of legacy thinking and familiar-but-soon-to-be-discarded technology, or an “avenue of opportunity” for a commercially successful and environmentally responsible future? There seem to be many “leap of faith” decisions involved, but in the “big picture” perspective replicating past conceptual and technical limitations is not an option either.